新闻资讯

联系我们

名 称:苏州赛森电子科技有限公司

电 话:0512-58987901

传 真:0512-58987201

邮 箱:sales@cycas.com

地 址:江苏省张家港经济开发区福新路1202号 215600PRC

网 址:www.cycas.com

Name: Suzhou cycas Microelectronics Co., Ltd.

Tel.: 0512-58987901

Fax: 0512-58987201

Email: sales@cycas.com

Address: No.1202,Fuxin Road,Zhangjiagang Economic Development Zone,Jiangsu Province 215600PRC

Website: www.cycas.com

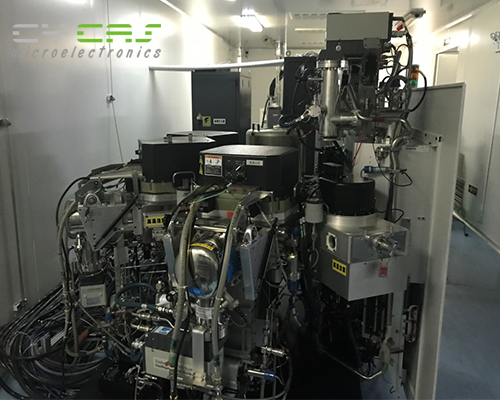

如何提高磁控溅射台的溅射效率?How to improve sputtering efficiency of magnetron sputtering table?

如何提高磁控溅射台的溅射效率?How to improve sputtering efficiency of magnetron sputtering table?

发布日期:2018-01-04 作者:www.cycas.com 点击:

磁控溅射台通常的溅射方法,溅射效率不高。为了提高溅射效率,首先需要增加气体的离化效率。为了说明这一点,先讨论一下溅射过程。当经过加速的入射离子轰击靶材(阴极)表面时,会引起电子发射,在阴极表面产生的这些电子,开始向阳极加速后进人负辉光区,并与中性的气体原子碰撞,产生自持的辉光放电所需的离子。这些所谓初始电子(primary electrons )的平均自由程随电子能量的增大而增大,但随气压的增大而减小。在低气压下,离子是在远离阴极的地方产生,从而它们的热壁损失较大,同时,有很多初始电子可以以较大的能量碰撞阳极,所引起的损失又不能被碰撞引起 的次级发射电子抵消,这时离化效率很低,以至于不能达到自持的辉光放电所需的离子。通过增大加速电压的方法也同时增加了电子的平均自由程,从而也不能有效地增加离化效率。虽然增加气压可以提高离化率,但在较高的气压下,溅射出的粒子与气体的碰撞的机会也增大,实际的溅射率也很难有大的提高。如果加上一平行于阴极表面的磁场,就可以将初始电子的运动限制在邻近阴极的区域,从而增加气体原子的离化效率。

常用磁控溅射仪主要使用圆筒结构和平面结构,这两种结构中,磁场方向都基本平行于阴极表面,并将电子运动有效地限制在阴极附近。磁控溅射的制备条件通常是,加速电压:300~800V,磁场约:50~300G,气压:1 ~10 mTorr,电流密度:4~60mA/cm ,功率密度:1~40W/cm ,对于不同的材料最大沉积速率范围从100nm/min到1000nm/min。同溅射一样,磁控溅射也分为直流(DC)磁控溅射和射频(RF)磁控溅射。射频磁控溅射中,射频电源的频率通常在50~30MHz。射频磁控溅射相对于直流磁控溅射的主要优点是,它不要求作为电极的靶材是导电的。因此,理论上利用射频磁控溅射可以溅射沉积任何材料。由于磁性材料对磁场的屏蔽作用,溅射沉积时它们会减弱或改变靶表面的磁场分布,影响溅射效率。因此,磁性材料的靶材需要特别加工成薄片,尽量减少对磁场的影响。

The sputtering efficiency of magnetron sputtering table is not high. In order to improve the sputtering efficiency, the first step is to increase the gas ionization efficiency. In order to illustrate this point, the sputtering process is discussed first. When the accelerated incident ion bombards the target (cathode) surface, it will cause electron emission. These electrons generated on the cathode surface start to accelerate towards the anode and enter the negative glow region, and collide with the neutral gas atoms to generate the ions needed for self-sustaining glow discharge. The mean free path of these so-called primary electrons increases with the increase of electron energy, but decreases with the increase of air pressure. At low pressure, ions are generated far away from the cathode, so their hot wall loss is large. At the same time, many initial electrons can collide with the anode with a large amount of energy, and the loss can not be offset by the secondary emission electrons caused by collision. At this time, the ionization efficiency is very low, so that the ions required for self-sustaining glow discharge cannot be achieved. By increasing the accelerating voltage, the mean free path of the electron is also increased, so the ionization efficiency cannot be increased effectively. Although the ionization rate can be increased by increasing the air pressure, the chance of collision between the splashed particles and the gas is also increased at a higher air pressure, and the actual sputtering rate is also difficult to be greatly improved. If a magnetic field parallel to the cathode surface is added, the motion of the initial electron can be limited to the region adjacent to the cathode, thus increasing the ionization efficiency of the gas atom.

The commonly used magnetron sputtering instrument mainly uses cylinder structure and plane structure. In these two structures, the magnetic field direction is basically parallel to the cathode surface, and the electron movement is effectively limited near the cathode. The preparation conditions of magnetron sputtering are: acceleration voltage: 300-800v, magnetic field: about 50-300g, air pressure: 1-10mtorr, current density: 4-60ma / cm, power density: 1-40w / cm, and the maximum deposition rate range for different materials is from 100nm / min to 1000nm / min. Like sputtering, magnetron sputtering can be divided into DC magnetron sputtering and RF magnetron sputtering. In RF magnetron sputtering, the frequency of RF power supply is usually 50-30mhz. The main advantage of RF magnetron sputtering over DC magnetron sputtering is that it does not need to be conductive as the target of electrode. Therefore, theoretically, any material can be deposited by RF magnetron sputtering. Due to the shielding effect of magnetic materials on the magnetic field, they will weaken or change the magnetic field distribution on the target surface and affect the sputtering efficiency. Therefore, the target materials of magnetic materials need to be specially processed into thin sheets to minimize the impact on the magnetic field.

本文网址:http://www.cycas.com/news/357.html

相关标签:磁控溅射台

最近浏览:

相关产品:

相关新闻:

- How to improve the utilization rate is the key point of vacuum magnetron sputtering coating industry如何提高利用率是真空磁控溅射镀膜行业的重点

- Sputtering is to bombard the target surface with charged particles in vacuum溅射镀膜就是在真空中利用荷能粒子轰击靶表面

- 磁控溅射种类?Magnetron sputtering type?

- 真空退火炉工艺布置及高温密封圈概况Process layout and high temperature sealing ring of vacuum annealing furnace

- 磁控溅射的工作原理Working principle of magnetron sputtering

- Magnetron sputtering has two characteristics of "low temperature" and "high speed"磁控溅射具有“低温”、“高速”两大特点Magnetron sputtering has two characteristics of

- 磁控溅射设备的主要用途Main uses of magnetron sputtering equipment

- What are balanced magnetron sputtering and unbalanced magnetron sputtering?什么是平衡磁控溅射和非平衡磁控溅射?

- 快速退火炉维修注意事项:Precautions for maintenance of rapid annealing furnace:

- 磁控溅射各有不同工作原理和应用对象Magnetron sputtering has different working principles and application objects