新闻资讯

联系我们

名 称:苏州赛森电子科技有限公司

电 话:0512-58987901

传 真:0512-58987201

邮 箱:sales@cycas.com

地 址:江苏省张家港经济开发区福新路1202号 215600PRC

网 址:www.cycas.com

Name: Suzhou cycas Microelectronics Co., Ltd.

Tel.: 0512-58987901

Fax: 0512-58987201

Email: sales@cycas.com

Address: No.1202,Fuxin Road,Zhangjiagang Economic Development Zone,Jiangsu Province 215600PRC

Website: www.cycas.com

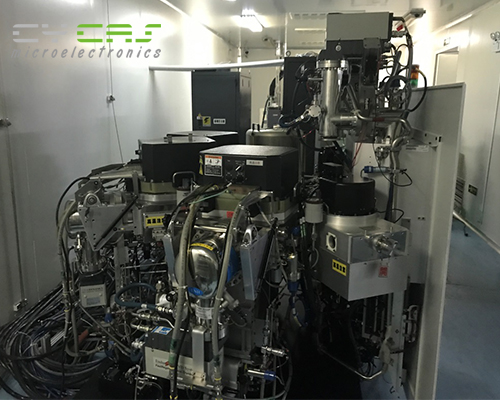

How to improve the utilization rate is the key point of vacuum magnetron sputtering coating industry如何提高利用率是真空磁控溅射镀膜行业的重点

How to improve the utilization rate is the key point of vacuum magnetron sputtering coating industry如何提高利用率是真空磁控溅射镀膜行业的重点

发布日期:2019-08-31 作者:www.cycas.com 点击:

磁控溅射靶材的利用率可成为磁控溅射源的工程设计和生产工艺成本核算的一个参数。截止2012年,还没有见到对磁控溅射靶材利用率专门或系统研究的报道,而从理论上对磁控溅射靶材利用率近似计算的探讨具有实际意义。对于静态直冷矩形平面靶,即靶材与磁体之间无相对运动且靶材直接与冷却水接触的靶, 靶材利用率( 最大值) 数据多在20%~30%左右(间冷靶相对要高一些,但其被刻蚀过程与直冷靶相同,不作专门讨论),且多为估计值。为了提高靶材利用率,研究出来了不同形式的动态靶,其中以旋转磁场圆柱靶最著名且在工业上被广泛应用,据称这种靶材的利用率最高可超过70%,但缺少足够数据或理论证明。常见的磁控溅射靶材从几何形状上看有三种类型:矩形平面、圆形平面和圆柱管

如何提高利用率是真空磁控溅射镀膜行业的重点,圆柱管靶利用高,但在有些产业是不适用。

磁控溅射台利用外加磁场捕捉电子,延长和束缚电子的运动路径,搞高离化率,增加镀膜速率。

1)溅射粒子(主要是原子,还有少量离子等)的平均能量达几个电子伏,比蒸发粒子的平均动能kT高得多(3000K蒸发时平均动能仅0.26eV),溅射粒子的角分布与入射离子的方向有关。(2)入射离子能量增大(在几千电子伏范围内),溅射率(溅射出来的粒子数与入射离子数之比)增大。入射离子能量再增大,溅射率达到极值;能量增大到几万电子伏,离子注入效应增强,溅射率下降。(3)入射离子质量增大,溅射率增大。(4)入射离子方向与靶面法线方向的夹角增大,溅射率增大(倾斜入射比垂直入射时溅射率大)。(5)单晶靶由于焦距碰撞(级联过程中传递的动量愈来愈接近原子列方向),在密排方向上发生优先溅射。(6)不同靶材的溅射率很不相同。

How to improve the utilization rate is the key point of vacuum magnetron sputtering coating industry

The utilization ratio of magnetron sputtering target can be a parameter of engineering design and production cost accounting of magnetron sputtering source. Up to 2012, no special or systematic study on the utilization rate of magnetron sputtering target has been reported, but the theoretical study on the approximate calculation of the utilization rate of magnetron sputtering target has practical significance. For the static straight cold rectangular plane target, i.e. the target has no relative movement between the target and the magnet and the target is in direct contact with the cooling water, the target utilization (maximum value) data are mostly about 20% ~ 30% (the intercooled target is relatively higher, but its etching process is the same as that of the straight cold target, which is not specially discussed), and most of them are estimated values. In order to improve the target utilization, different forms of dynamic targets have been developed, among which the rotating magnetic field cylinder target is the most famous and widely used in industry. It is said that the highest utilization rate of this target can exceed 70%, but there is lack of sufficient data or theoretical proof. There are three types of common magnetron sputtering target materials in terms of geometry: rectangular plane, circular plane

and how to improve the utilization ratio of cylindrical tube are the key points of the vacuum magnetron sputtering coating industry. The utilization of cylindrical tube target is high, but it is not applicable in some industries.

The magnetron sputtering platform uses an external magnetic field to capture electrons, extend and bind the motion path of electrons, increase the ionization rate and coating rate.

1) The average energy of sputtered particles (mainly atoms, a small amount of ions, etc.) is several electron volts, much higher than the average kinetic energy KT of evaporated particles (the average kinetic energy of 3000K evaporation is only 0.26ev). The angular distribution of sputtered particles is related to the direction of incident ions. (2) The sputtering rate (the ratio of the number of sputtering particles to the number of incident ions) increases with the increase of incident ion energy (in the range of several thousand electron volts). When the energy of incident ion increases again, the sputtering rate reaches the extreme value; when the energy increases to tens of thousands of electron volts, the ion implantation effect increases and the sputtering rate decreases. (3) The sputtering rate increases with the increase of the incident ion mass. (4) The angle between the direction of the incident ion and the normal direction of the target surface increases, and the sputtering rate increases (the sputtering rate of oblique incidence is larger than that of vertical incidence). (5) Due to the focal length collision (the momentum transferred in the cascade process is more and more close to the atomic array direction), the sputtering takes place preferentially in the dense array direction. (6) The sputtering rate of different targets is very different.

本文网址:http://www.cycas.com/news/354.html

相关标签:磁控溅射台

最近浏览:

相关产品:

相关新闻:

- 磁控溅射设备的主要用途Main uses of magnetron sputtering equipment

- 磁控溅射的工作原理Working principle of magnetron sputtering

- 磁控溅射种类?Magnetron sputtering type?

- 真空退火炉工艺布置及高温密封圈概况Process layout and high temperature sealing ring of vacuum annealing furnace

- Magnetron sputtering has two characteristics of "low temperature" and "high speed"磁控溅射具有“低温”、“高速”两大特点Magnetron sputtering has two characteristics of

- Study on the properties of aluminum plating by electron beam evaporation and magnetron sputtering电子束蒸发与磁控溅射镀铝性能分析研究

- 磁控溅射各有不同工作原理和应用对象Magnetron sputtering has different working principles and application objects

- Sputtering is to bombard the target surface with charged particles in vacuum溅射镀膜就是在真空中利用荷能粒子轰击靶表面

- What are balanced magnetron sputtering and unbalanced magnetron sputtering?什么是平衡磁控溅射和非平衡磁控溅射?

- 快速退火炉维修注意事项:Precautions for maintenance of rapid annealing furnace: