新闻资讯

联系我们

名 称:苏州赛森电子科技有限公司

电 话:0512-58987901

传 真:0512-58987201

邮 箱:sales@cycas.com

地 址:江苏省张家港经济开发区福新路1202号 215600PRC

网 址:www.cycas.com

Name: Suzhou cycas Microelectronics Co., Ltd.

Tel.: 0512-58987901

Fax: 0512-58987201

Email: sales@cycas.com

Address: No.1202,Fuxin Road,Zhangjiagang Economic Development Zone,Jiangsu Province 215600PRC

Website: www.cycas.com

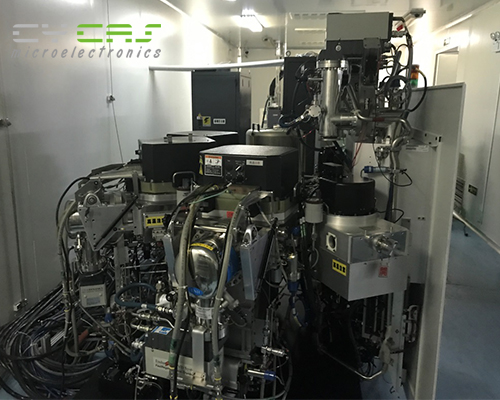

赛森电子带您了解高真空磁控溅射台Cycas electronics show you the high vacuum magnetron sputtering table

赛森电子带您了解高真空磁控溅射台Cycas electronics show you the high vacuum magnetron sputtering table

发布日期:2018-01-03 作者:www.cycas.com 点击:

赛森电子带您了解高真空磁控溅射台

1. 设备基本构造形式:该设备系是涡轮分子泵+机械泵抽气的单室高真空全不锈钢系统。主真空室下底盘上安装ф50三支磁控靶。真空室上盖上安装样品转盘,样品转盘由水冷和加热炉两套组成,二者不能同时兼用,只能交替使用(系统需要暴露空气,更换转盘)。水冷转盘下方可放置六片ф40样品,每片样品均可在计算机控制下制备多层膜,镀完膜的样品可手动公转换位。加热转盘只携挂一片样品, 做周向±180°转动。在计算机控制下制备多层膜。除大法兰密封口、转盘转动密封及磁控除大法兰盖和磁控靶靶头采用氟胶圈密封外,其余均按超高真空要求设计,采用无氧铜圈金属密封。

2. 真空系统采用FB600涡轮分子泵+2XZ-8机械泵抽气;真空室经24小时连续烘烤后,其极限真空≤6.6 10-5pa;系统从大气开始抽气,在≤30分钟内,其真空度≤6.6 10-4pa;停泵关机12小时后,系统真空度≤5pa,其真空度采用DL-9复合真空计测量。

3. Ф50、水冷、RF和DC兼容磁控靶三支,均有各自的电动挡板。

4. 样品尺寸Ф40、分水冷和加热炉转盘、二者更换交替使用。在样品下加装挡板。样品加热温度400±1°(加热炉做周向±80°回转)。

5. 电源采用RF射频电源N=500W f=13.5MHZ一台;DC直流稳流电源N=500W 1A 500V 两台。

6. 进气系统采用两路MFC质量流量计控制。另一路用手动进气阀直接进气。

7. 实验过程中系统的复位功能、确认靶位功能、溅射镀膜时间控制功能、回转控制功能均由计算机控制。

Cycas electronics takes you to know about the high vacuum magnetron sputtering Table

Basic structure of the equipment: the equipment is a single chamber high vacuum all stainless steel system pumped by turbomolecular pump + mechanical pump. Three ф 50 magnetic control targets are installed on the chassis under the main vacuum chamber. A sample turntable is installed on the upper cover of the vacuum chamber. The sample turntable is composed of two sets of water-cooling and heating furnace, which can not be used at the same time and can only be used alternately (the system needs to expose air and replace the turntable). Six ф 40 samples can be placed under the water-cooled turntable. Each sample can be prepared under the control of a computer. The coated sample can be rotated manually. Only one sample is carried by the heating rotary table and rotated in a circumferential direction of ± 180 °. Multilayers were prepared under the control of computer. Except for the large flange seal port, rotary seal of rotary table and magnetic control, except that the large flange cover and magnetic control target head are sealed with fluorine rubber ring, the rest are designed according to the requirements of ultra-high vacuum and sealed with oxygen free copper ring metal.

The vacuum system adopts fb600 turbomolecular pump + 2xz-8 mechanical pump to pump air; after the vacuum chamber is baked continuously for 24 hours, its limit vacuum is ≤ 6.610-5pa; the system starts to pump air from the atmosphere, and its vacuum degree is ≤ 6.610-4pa within ≤ 30 minutes; after the pump is stopped and shut down for 12 hours, the system vacuum degree is ≤ 5pa, and its vacuum degree is measured by dl-9 composite vacuum meter.

Three Ф 50, water-cooled, RF and DC compatible magnetron targets, each with its own electric baffles.

The sample size is Ф 40, the water cooling and heating furnace turntable are replaced and used alternately. Install baffle under the sample. The heating temperature of the sample is 400 ± 1 ° (the heating furnace rotates in a circumferential direction of ± 80 °).

One RF power supply n = 500W f = 13.5mhz and two DC current stabilized power supplies n = 500W 1A 500V are adopted.

The air intake system is controlled by two MFC mass flow meters. The other way uses the manual intake valve to directly intake air.

During the experiment, the reset function, target position confirmation function, sputtering coating time control function and rotation control function of the system are all controlled by the computer.

本文网址:http://www.cycas.com/news/352.html

相关标签:磁控溅射台

最近浏览:

相关产品:

相关新闻:

- 磁控溅射设备的主要用途Main uses of magnetron sputtering equipment

- 磁控溅射的工作原理Working principle of magnetron sputtering

- 快速退火炉维修注意事项:Precautions for maintenance of rapid annealing furnace:

- Magnetron sputtering has two characteristics of "low temperature" and "high speed"磁控溅射具有“低温”、“高速”两大特点Magnetron sputtering has two characteristics of

- What are balanced magnetron sputtering and unbalanced magnetron sputtering?什么是平衡磁控溅射和非平衡磁控溅射?

- 真空退火炉工艺布置及高温密封圈概况Process layout and high temperature sealing ring of vacuum annealing furnace

- How to improve the utilization rate is the key point of vacuum magnetron sputtering coating industry如何提高利用率是真空磁控溅射镀膜行业的重点

- 磁控溅射种类?Magnetron sputtering type?

- 磁控溅射各有不同工作原理和应用对象Magnetron sputtering has different working principles and application objects

- Sputtering is to bombard the target surface with charged particles in vacuum溅射镀膜就是在真空中利用荷能粒子轰击靶表面